Technical textiles

- Conveyor belts

- Coated fabrics

- Inflatable structures

- Lamination of textiles with each other or with membranes

- Gloves

Most synthetic fibers consist of different thermoplastic polymers such as polyester or polyamide. Consequently, they can be welded as well.

Natural fibers such as cotton, wool, and silk do not consist of thermoplastic polymers and can therefore not be welded.

For conveyor belts laser welding can be used to join the belt ends or, for open-mesh structures, to join the crossing points between warp and weft threads.

In the case of coated textiles, the coatings can be welded together to create air- or watertight structures. It is not necessary to subsequently seal the seams, as is the case of sewing.

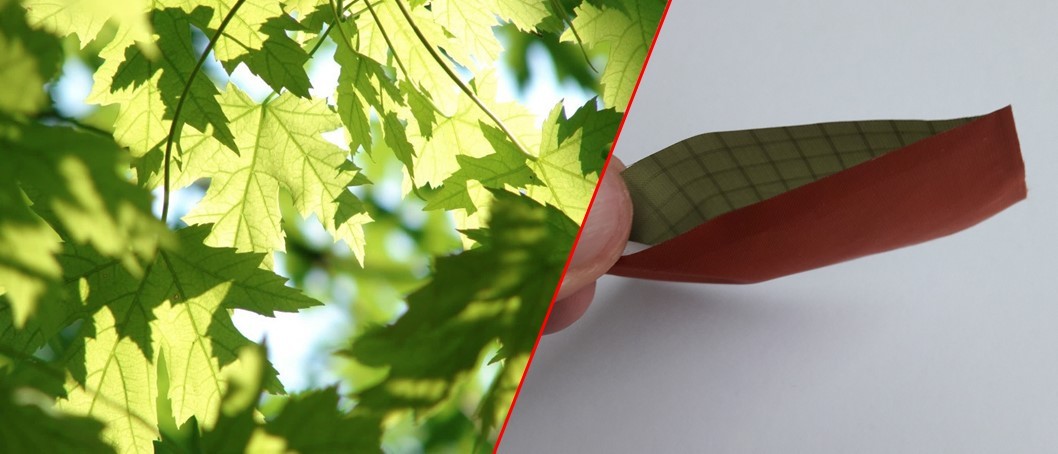

Laser welding can also be used to laminate textiles with each other or with foils or membranes - full-surface or structured to add further functionalities.

The clothing sector within the textile industry is difficult for laser welding. On the one hand for the technical reasons listed below, but on the other hand also due to today's value chain and prices for clothing.

The laser-transparent and laser-absorbing materials required for laser welding are in contrast with the frequent color changes in collections. Outdoor clothes are often treated with a water-repellent surface treatment that also acts as a separating layer for welding.

In addition, many garments require three-dimensional contours, which makes automated production in different sizes more difficult. Welding in just two dimensions flat on a plane surface is much easier to solve as for example for gloves.