Axes or scanner

The selection of the motion system is closely related to the type of welding process.

For very fast movements during quasi-simultaneous welding, the scanner head is the right choice. Since only the two deflection mirrors have to be rotated in x and y direction, high speeds of up to several meters per second are possible.

More information about the scanner can be found in the product section optics.

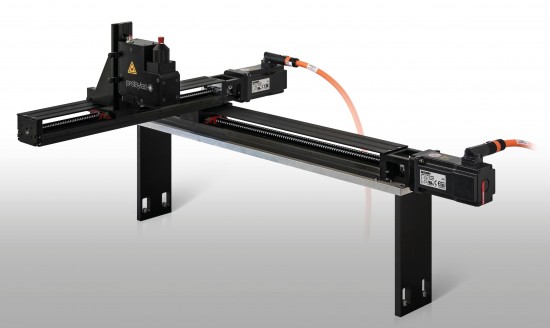

For slower movements in the contour process of typically a few centimeters per second, axes systems driven by servo motors are used.

Two axes in x and y direction are usually required.

If the parts have a slightly three-dimensional weld seam geometry or if welds at different heights are required, an additional z-axis can be useful.

A single axis can be used as a rotation axis for welding around the circumference of a cylindrical component. A single axis combined with a line optic makes allows for welding a complete area.

With the simultaneous process type no movement is necessary, since the contour is formed by the optics. If multiple parts have to be welded one after each other, the optics for simultaneous process can also be mounted on an xy-axis system.