Beam profile laser

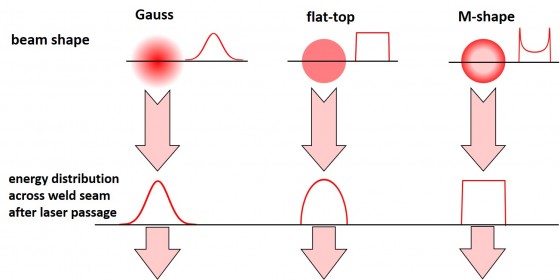

Depending on the type of laser, the beam profile of the laser may look different. Optical elements can also be used to change the beam profile.

Normally the Gaussian beam profile is regarded as optimal. It can best be focused to a small spot, as needed for metal cutting or marking.

However, for welding plastics the Gaussian beam profile is not optimal. If one moves along a weld seam, more energy is absorbed in the middle of the weld seam than at the edges. This can lead to burns in the middle of the weld seam or poorly defined edges of the weld seam.

The normally used diode lasers have a more or less rectangular beam profile (flat-top). The energy absorbed in the weld seam is distributed more evenly across the width of the weld seam. The quality of the weld seam is better and the process window of the welding parameters more tolerant than for Gaussian beam profiles.

In principle, the optimum beam profile for plastic welding is a ring-shaped beam profile with less intensity in the middle than at the edge. This is also known as an M-shaped beam profile. The weld seam receives the same energy density over its entire width.

However, at least one additional optical element (lenses or diffractive optical element DOE) is required to form an M-shaped beam profile.

In the case of semi-crystalline polymers or plastics with light-scattering additives, the beam profile in the upper component is changed. It becomes blurred and approaches a similar shape to the Gaussian beam profile.

Special beam shaping therefore only makes sense with amorphous plastics that do not deteriorate the beam profile.