Light scattering

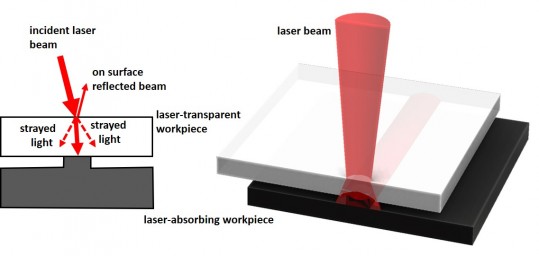

In addition to absorption, scattering can reduce the transmission of the laser beam through the upper part.

By scattering, the light is deflected from the original direction so that it cannot reach the weld seam anymore.

Origin of strong light scattering can be

- crystallites in the polymer

- pigments

- mineral fillers

- fibers

- other particles or inhomogeneities

Many technical polymers are semi-crystalline and scatter the light so that the upper part cannot be any thickness. How strongly the light is scattered depends on the type of polymer. For example, for POM and PBT the scattering is strong, so that the maximum thickness is only 1-2 mm. With PEEK, the maximum thickness even drops to about 1 mm.

The scattering of polymers may also depend on additives and processing. For example, the crystallite size can be influenced to reduce scattering.

There are crystal-clear variants of PP, which are mainly used in the packaging industry.

For PBT, there are special less scattering variants that also allow components several millimeters thick to be welded (e.g. Ultradur® Lux from BASF).

Pigments that produce a highly opaque color are delicate for laser plastic welding. The scattering is only slightly dependent on the wavelength of the light, so that the laser, like light for the eye, cannot pass through the upper part. Deeply white pigments such as titanium dioxide in household appliances are not possible in laser-transparent parts.

Mineral fillers used for example to change the mechanical properties of plastics can also be tricky if they lead to a nontransparent coloration.

Glass fibers are usually not so sensitive to light scattering if they are not incorporated in very high concentrations or if the part are very thick.

Glass balls scatter the light very strongly and prevent laser welding even with small thicknesses of the upper part.